Home

Preparation

Empennage

Wings

Fuselage

Engine

Finish Kit

Favorite Links

W & B Calculator

Van's Aircraft

Email Me

|

|

Engine Update February 2009 Updates

|

|

February 22, 2009

Back to Baffle Work.... - 4.0 hrs

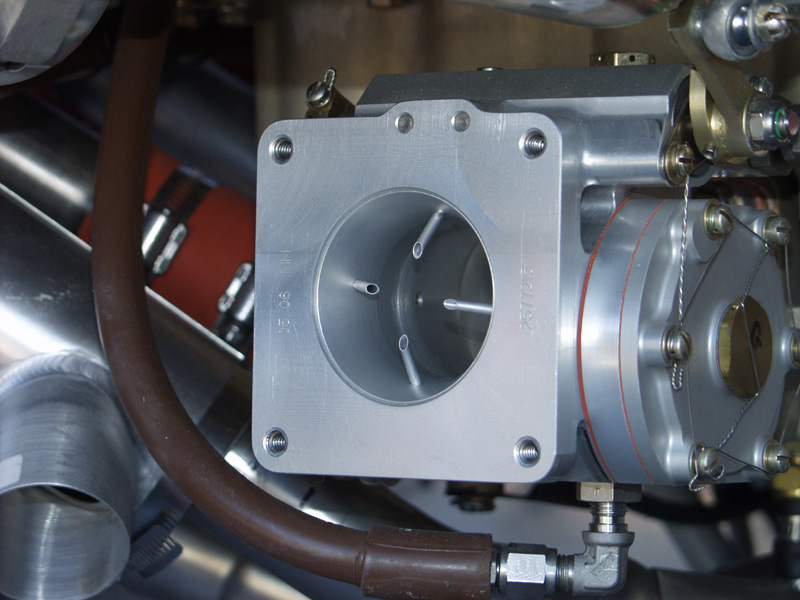

Yesterday was fun but today its time to get back to work. Today started with cleaning up the duct tape residue off the fuel injector. I used alcohol but that was not strong enough. Ended up using MEK. That stuff will take anything off.

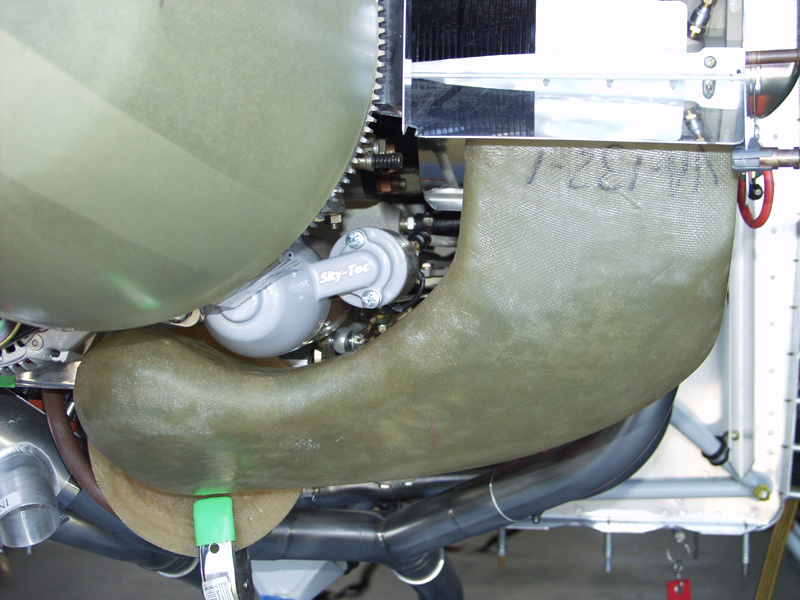

Once that was done I mixed up some Superfil and filled up some of the small holes left from the last flox work. This stuff mixes up nice and seems easy to work with. Set that aside to cure and then back to the FAB.

Next I used a hole saw to drill out a 2 and 1/4 piece of wood and taped it into the hole in the injector. Then I put the FAB onto the front of the injector and clamped it in place. Next I measure and trimmed the top edge of the FAB to match the floor of the left baffle inlet. After several cuts and refits I think it still needs to fit a bit closer to the starter which will give me more edge distance from the outside cylinder baffle piece.

I marked the outside edge of the FAB on the bottom floor of the baffle inlet. Decided not to cut this hole yet. Need to do some more research first. These baffle plans dont show any fitting of a horizontal injection type setup.

This website was built to document my work in compliance with the FAA requirements

needed to certify my aircraft.

My experiences and comments are by no means to be

considered as instructions on how to build any aircraft.

|

| |